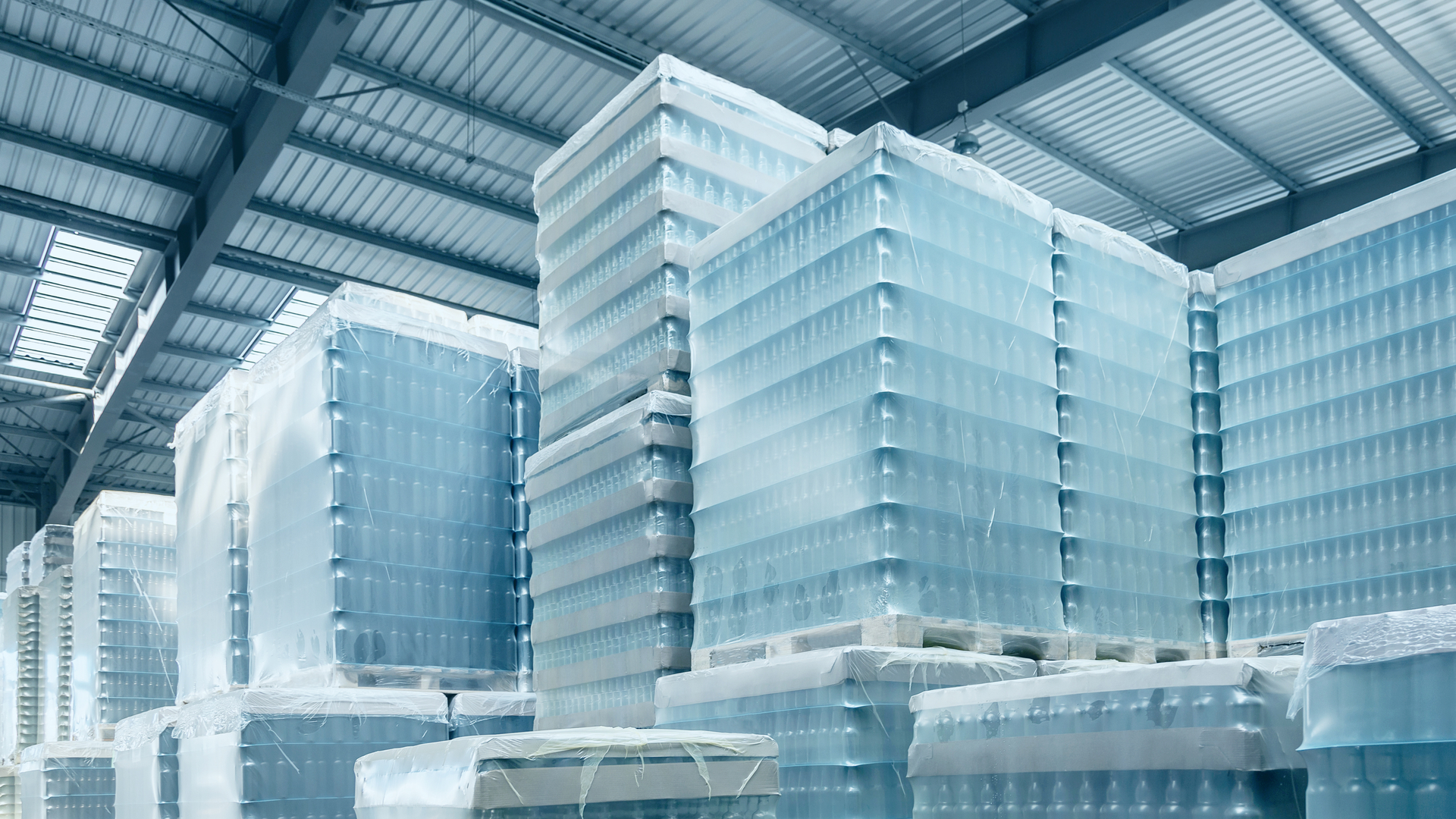

Automatisierte Beladelösungen für dieGetränkeindustrie

Mit weniger Aufwand mehr erreichen, durch automatisches Beladen

Die Anforderungen an steigende Mengen, Produktvielfalt, Rückverfolgbarkeit und Nachhaltigkeit stellen Getränkehersteller vor große Herausforderungen. Gleichzeitig besteht der Bedarf, die Lieferkette zu optimieren, um sie zuverlässiger und sicherer zu gestalten. Wir bei Actiw wissen, wie die Automatisierung der Outbound-Logistik Ihnen hilft, den Durchsatz zu erhöhen, die Kosten zu senken und die Sicherheit und Nachhaltigkeit in Ihren Beladeprozessen zu verbessern.

Vorteile für die Getränkeindustrie

- Steigerung des Durchsatzes – 3 Lkw pro Stunde mit komplexen Beladungsmustern über eine Laderampe

- Vereinfachung Ihrer Verladeprozesse – Bereitstellung und Verladung von Paletten in einem Schritt

- Reduzierung der Lkw-Standzeiten

- Niedrigere Betriebskosten durch Automatisierung

- Minimierung von manuellen Fehlern und Produktschäden

- Verbessern Sie die Sicherheit und Umwelteffizienz, indem Sie Gabelstapler von der Laderampe entfernen

Actiw-Lösungen bei der Arbeit

Actiw-Lösungen für die Getränkeindustrie

Nothing found.

Automatisierung der Getränkeverladung

- Geeignet für palettierte oder palettenlose Produkte, mit Zwischenlagen

- Auch für komplexe Lademuster geeignet

- Geeignet für verschiedene Palettentypen in derselben Ladung

- Ermöglicht und erhöht die Nachvollziehbarkeit des Prozesses, jede Palette kann automatisch nachverfolgt werden

- Anwendbar auf den bestehenden Fuhrpark, keine Änderung erforderlich

- Integrierbar in jede vorgelagerte Lagerautomatisierung (ASRS, FLT, AGVs usw.)

- Einfache Plug-and-Play-Integration in bestehende WMS- und ERP-Systeme

REFERENZ GETRÄNKEBRANCHE

Coca-Cola Enterprises Norge AS

Actiw automatisierte das Produktionslager des Unternehmens, um die vorhandene Lagerfläche mit hoher Umschlagkapazität optimal zu nutzen. Automatisierte Lagerlösungen puffern, sortieren und stellen palettierte Ladungen in exakter Reihenfolge für Lkw-Beladungen bereit.